您的位置:首页 > 产品中心 > 3D Printable Yttria-stabilized Zirconium(IV) Oxide Ink

3D Printable Yttria-stabilized Zirconium(IV) Oxide Ink

产品别名

3D Printable Yttria-stabilized Zirconium(IV) Oxide Ink

YSZ ink

3D printable ceramic ink

Yttria stabilized zirconia ink

3Y-ZrO2 ink

Yttrium stabilized zirconium oxide ink

产品性质

| description【描述】 | Printing methods compatible with: Direct-Ink-Writing 3D printing |

| Quality Level【质量水平】 | 100 |

| form【形式】 | paste |

| greener alternative product characteristics【环保替代产品特性】 | Design for Energy Efficiency Learn more about the Principles of Green Chemistry. |

| concentration【浓度】 | 70 wt. % (Yttria stabilized zirconia) |

| color【颜色】 | white |

| Particle size【粒径】 | 120 nm |

| Viscosity【粘度】 | 2-25 Pa.s(25 ℃) (@ shear rate of 100 s-1) |

| greener alternative category【环保替代产品分类】 | Enabling |

| storage temp.【储存温度】 | 2-8℃ |

基本信息

| General description【一般描述】 | We are committed to bringing you Greener Alternative Products, which adhere to one or more of The 12 Principles of Green Chemistry. This product has been enhanced for energy efficiency. Click here for more information. |

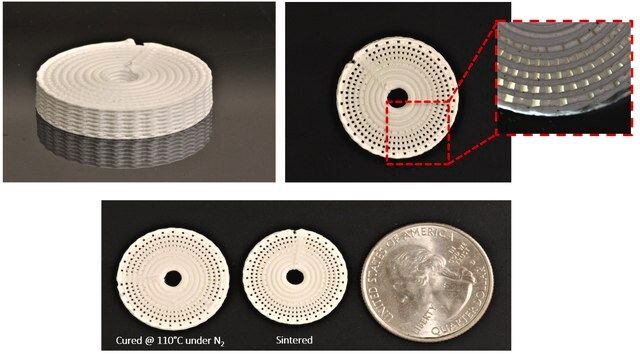

| Application【应用】 | This product is a thixotropic ink based on yttria stabilized zirconia (YSZ) nanoparticles. It is suitable for various direct ink write (aka robocasting) printing technologies [1,2,3,4]. The ink offers a stable dispersion of YSZ, high viscosity, good printability, and long shelf life. Annealed patterns provide excellent chemical resistance and high surface area. The ink is suitable for applications such as membranes, catalysis, separators and reactors. |

| Caution【注意】 | Handeling tips:

|

| Preparation Note【制备说明】 | Step-by-Step procedure for ink mixing and loading into syringe is in attached file. Direct-Ink-Writing (DIW) Notes:

Post Processing of DIW printed parts:

Ramp to 300℃ @ 1℃/min. Hold for 4 hours. Ramp to 400℃ @ 1℃/min. Hold for 2 hours. Ramp to 800℃ @ 2℃/min. Hold for 4 hours. Ramp to 1090℃ @ 2℃/min. Hold for 15 hours. Ramp down to 50℃ @ 2℃/min. |

产品说明

| Storage and Stability【储存及稳定性】 | Tighly seal remaining ink, and store in 2-8° C fridge. |

安全信息

| Pictograms【象形图】 | GHS05,GHS07 |

| Signal word【警示用语:】 | Danger |

| Hazard Statements | H315 - H317 - H318 - H335 |

| Precautionary Statements | P261 - P264 - P271 - P280 - P302 + P352 - P305 + P351 + P338 |

| Hazard Classifications【危险分类】 | Eye Dam. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3 |

| Target Organs【靶器官】 | Respiratory system |

| Storage Class Code【储存分类代码】 | 10 - Combustible liquids |

| WGK | WGK 3 |